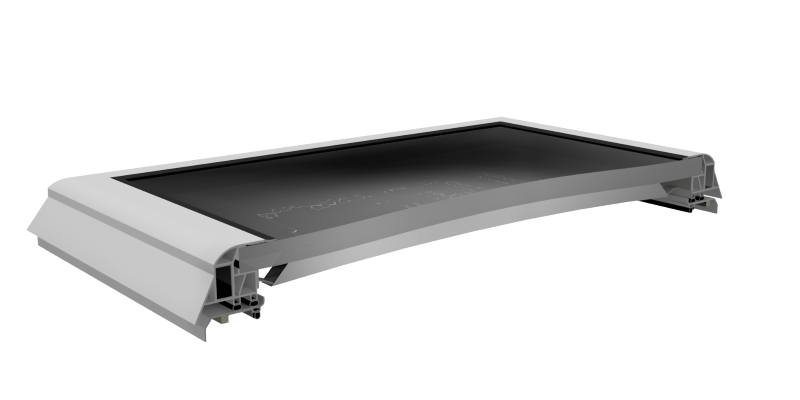

For energy efficient buildings it is required to use roof lights with high U-value. In this case polycarbonate is the superior choice for skylight material. Here are the 6 reasons why we think that polycarbonate is the best choice.

1. Adaptability

Unlike some of its popular competitors such as fibreglass, polycarbonate is completely transparent rather than translucent or opaque, so it has the clarity of glass with few of the drawbacks.

For example, one of the most obvious benefits of using polycarbonate is that it is extremely flexible. It can be easily adapted to curved profiles and, such is its malleability, this can be done on-site with no special equipment required.

It can also be drilled through easily and safely in order to make openings for cables or fixings if necessary. Polycarbonate can also be very easily cut to fit and trimmed to shape in situ, meaning that millimetre-perfect measurements and off-site manufacturing are usually not necessary.

This, in turn, means that architects are much better protected against wasted units and clients can cut down on overall wastage.

2. Weight

Another factor that makes polycarbonate such an attractive material is its lightness – it is less than half the weight of identically-sized units made of glass.

Of course, this makes it much easier for workers to handle – even with large pieces — and the structures needed to support it can also be less obtrusive, thus giving a cleaner line to the rooflight and the building in general.

There are also environmental benefits to its weight: for example, the very significant costs of transporting building materials are much lower with polycarbonate than many of its alternatives.

3. Environment-friendly

Polycarbonate has the edge when it comes to other green issues too: it takes less energy to produce than competing products and, unlike fibreglass/other glass alternatives, it is easily recyclable.

Polycarbonate can generally be collected and broken into granule-sized pieces by a wide range of companies and then used to manufacture everything from household plastic products to, more recently, the high-performance polymers used in medical equipment and fibre-optics.

4. Durability

Polycarbonate does not need regular replacing or maintenance as it has a very long life-expectancy: typically, it will keep its appearance, hold its shape and continue to perform for many years.

Despite this longevity, polycarbonate is also unique because, as long as it has a tint or filter applied, it does not discolour over time – alternative products typically start to yellow or cloud over after a few years. Lastly, polycarbonate will neither shatter nor fracture.

5. Resilience

In fact, its resilience is one of polycarbonate’s main selling points – it is able to withstand impact and is virtually shatter-proof, much more so than fibreglass.

This makes polycarbonate much more able to withstand extreme environmental conditions: it will not bend, break or fracture during, for example, hailstorms or under deep coverings of snow. It is popular in a wide range of countries because it is unaffected by both sub-zero temperatures and extreme heat (it keeps its rigidity from -50C to approximately 140C).

Polycarbonate also blocks 99% of harmful sun rays from entering a building by absorbing almost all UV rays that pass through it — it is more effective than high-factor sunscreen.

6. Insulation

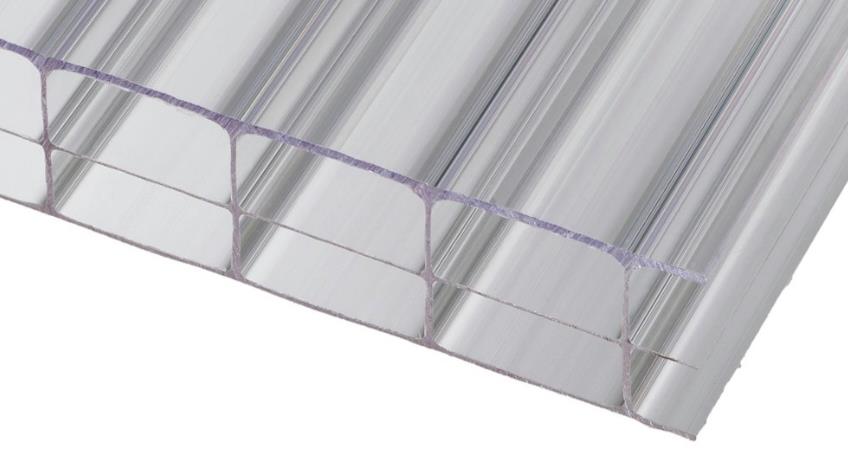

Polycarbonate has very low thermal conductivity which makes it a good insulator, particularly lightweight multiwall polycarbonate sheets which trap the cold air in their hollow interior in much the same way as traditional double-glazing. Plus, it has a very high ignition point of 580C which makes it very safe in the event of a fire.

Summary

Throughout the world, polycarbonate is becoming the most popular choice for rooflights. Some of the most respected architects in the world, including the Herzog and de Meuron and Norman Foster practices, have used polycarbonate as their skylight material to stunning effect.

en

en  lt

lt